RoRo terminals handle some of the most valuable and time-sensitive cargo in the global logistics chain. As volumes, regulatory pressures, and OEM expectations continue to rise, the yard itself must evolve from a large parking lot into a highly structured, digitally controlled operating environment.

This guide provides a practical, step-by-step framework that any RoRo or Finished Vehicle Logistics (FVL) terminal can use to improve yard layout, zoning, and digital addressing. The goal is to help terminals build a yard that is:

- Operationally efficient

- Digitally traceable

- Ready for automation and real-time visibility

Let’s walk through the fundamentals of how to structure a RoRo yard, from physical geometry to digital coding to real-time tracking.

Step 1: Establish the Physical Foundation, Geometry, Angles, and Standardization

To build a reliable digital address system, you must start with a structured, consistent physical yard layout.

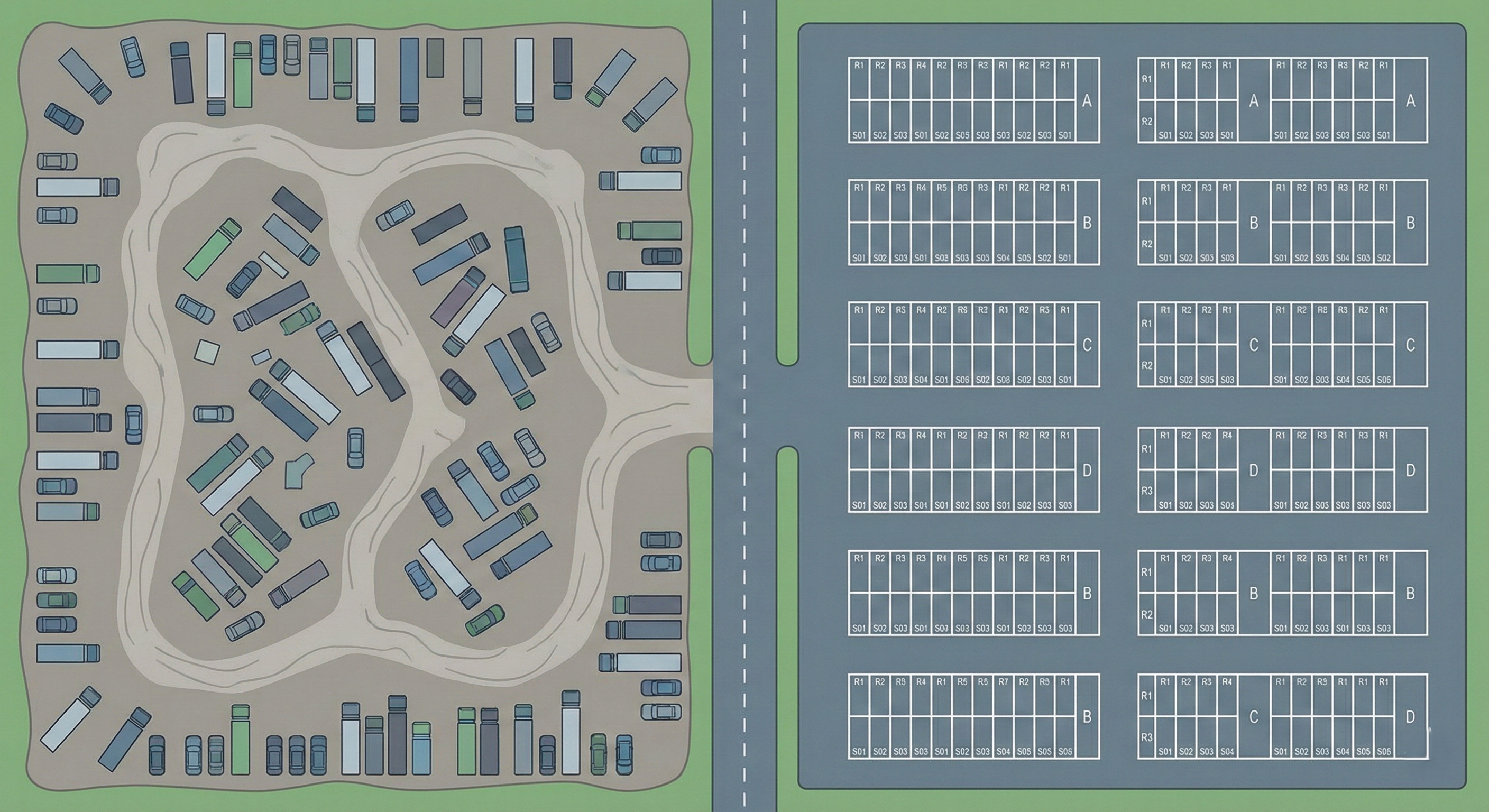

1.1 Choose the Right Parking Geometry

Identify the balance between density (how many vehicles fit) and flow (how fast they move):

- Large rectangular blocks are ideal for structured zoning.

- Blocks should be aligned for clear driver movement and future digital mapping.

1.2 Select the Optimal Parking Angle

Your choice affects flow efficiency, safety, and retrieval speed.

Parking AngleBenefitsTrade-Offs90°Simple layoutWide aisles; slower exits45°Best maneuverability; fast retrievalSlightly less dense than 60°60°Highest densityHarder to maneuver; riskier for high-volume ops

45° parking is widely recommended for RoRo terminals because it improves driver visibility, reduces steering corrections, and speeds up staging during vessel loading.

1.3 Standardize Slot and Aisle Dimensions

Consistency enables accurate digital mapping and reduces damage risk.

- Car slots: 8.5–9 ft × 18–20 ft

- SUV/Truck slots: ≥10 ft width

- Two-way aisles: 24–25 ft (depending on angle)

Standardization is essential for linking physical layout to digital systems like the YMS/TOS.

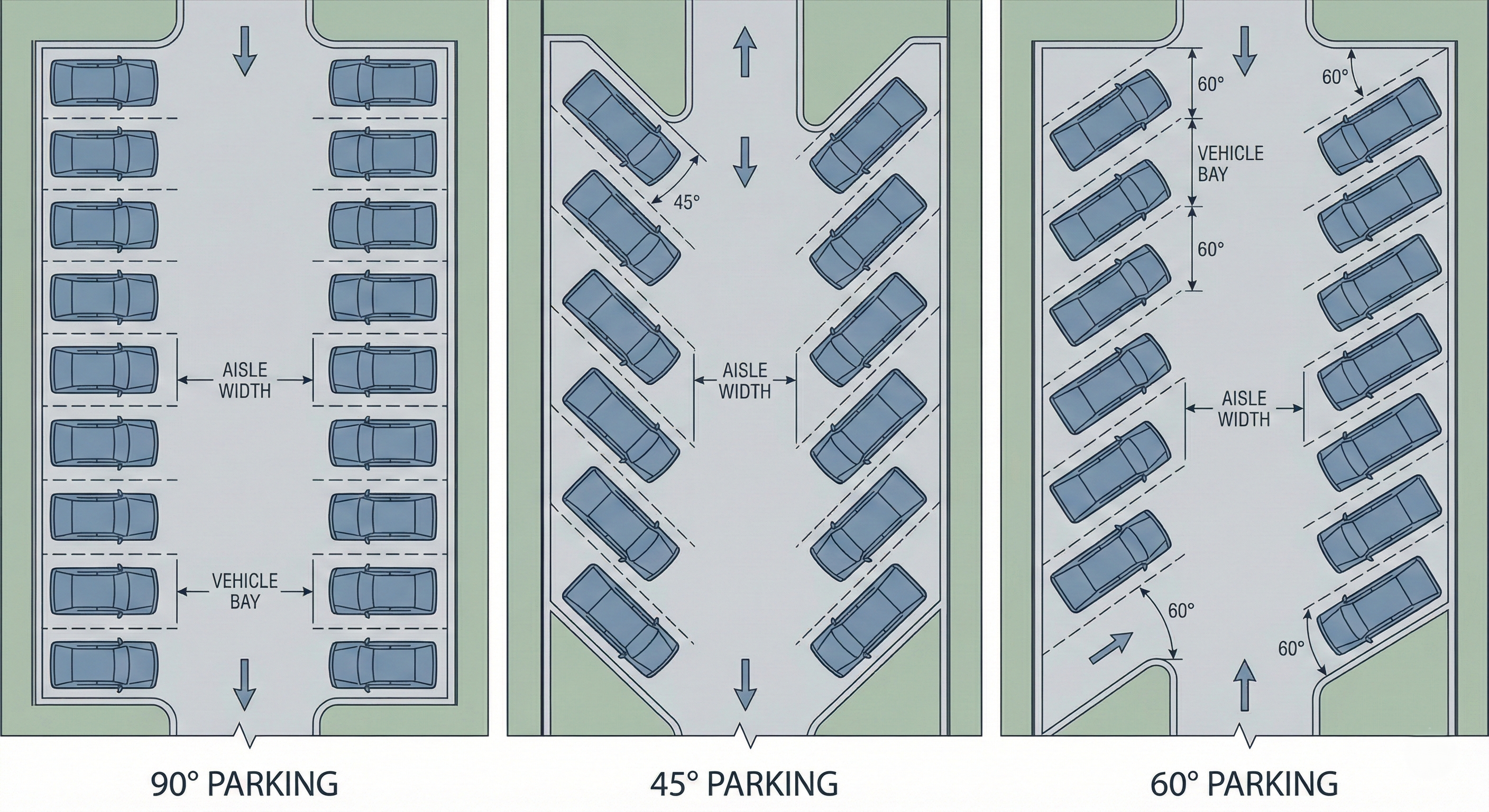

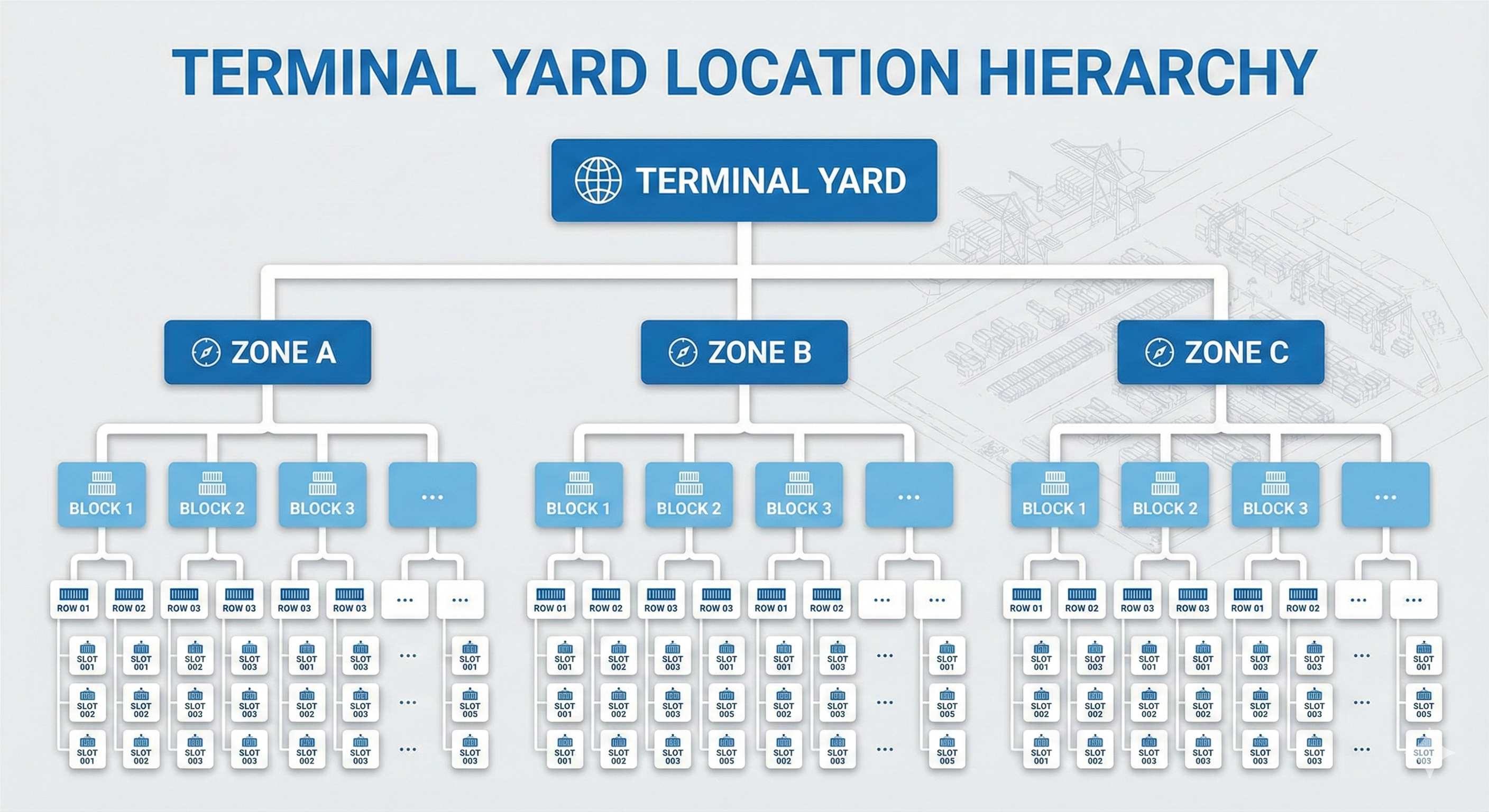

Step 2: Define Your Hierarchical Location Model, Zone, Block, Row, Slot

Once the yard is physically structured, give every location a unique digital identity through a four-level hierarchy.

2.1 Build the Four-Tier Model

- Zone (Z): Defines major operational areas (Export, Import, Customs, etc.)

- Block (B): A paved sub-area inside a zone

- Row (R): A linear string of parking spaces

- Slot (S): The individual vehicle position

Example: EX-015-R010-S025

This system ensures clarity for drivers, planners, and digital tools.

2.2 Use a Scalable Format

A proven format is:Z-BBB-RRR-SSS

This allows:

- 999 blocks

- 999 rows

- 999 slots per row

You future-proof your yard for expansion or reconfiguration.

2.3 Connect Physical Layout to Coordinates

Each slot should be mapped to yard coordinates (X,Y).

This allows integration with:

- GPS / RTK-DGPS

- RFID

- AI/vision-based RTLS

- TOS/YMS visualization tools

This mapping becomes the bridge between physical operations and digital accuracy.

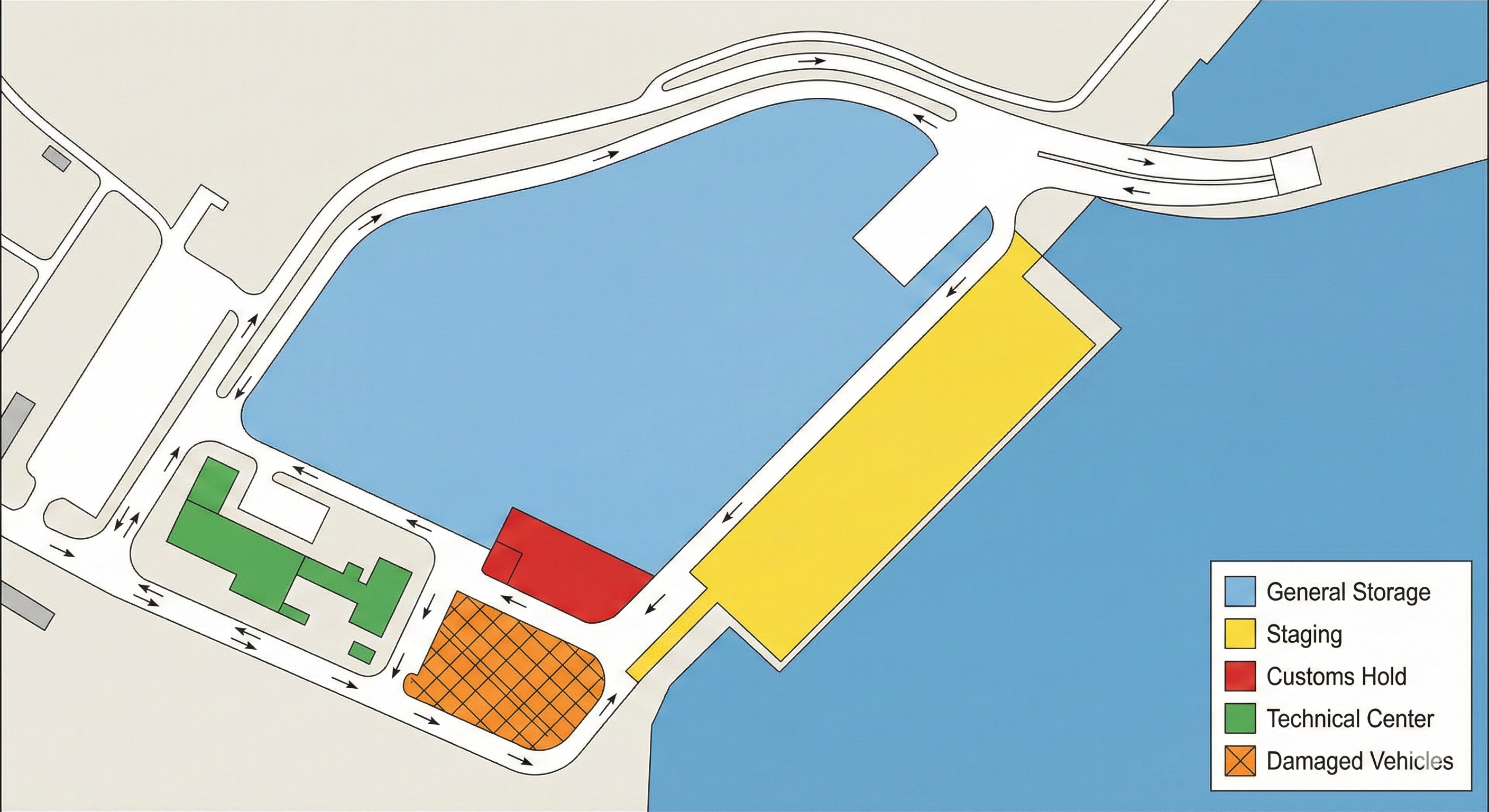

Step 3: Define Operational Zones and Compliance Areas

A high-performance yard separates vehicles based on what process they are in and what restrictions apply.

3.1 Set Up Core Operational Zones

- General Storage / Buffer: large areas for stable parking

- Staging / Ready-to-Load: near the quay, sequenced for vessel stowage

- Gate Processing: inbound/outbound truck control

Each zone should have a purpose tied to flow efficiency.

3.2 Include Mandatory Compliance Zones

Certain vehicle statuses require physical segregation:

- Customs Hold (CU)

- Technical Center (PDI/Repair)

- Unserviceable / Damaged (UNS)

- Dangerous Goods (IMDG)

These zones ensure legal compliance, safety, and streamlined control.

3.3 Align Zones With Digital Rules

If a vehicle enters a certain zone:

- Customs area → status automatically becomes Pending Hold

- Staging → status changes to Ready to Load (RTL)

- Technical Center → status becomes In Maintenance/PDI

This reduces errors and ensures the terminal’s system always matches reality.

Step 4: Implement Real-Time Location Systems (RTLS)

To achieve reliable inventory accuracy, the terminal must connect each vehicle’s physical location to its digital record.

4.1 Start With Reliable Identification

- VIN scanning

- QR/Barcode labels

- RFID tags (especially useful for automation)

4.2 Deploy RTLS for Slot-Level Precision

Outdoors:

- RTK-DGPS provides centimeter-level accuracy, ideal for verifying exact slot placement.

Indoors or high-density areas:

- UWB, CSS, or active RFID provide accuracy where GPS is weak.

4.3 Use AI Computer Vision Where Applicable

Cameras can be used for:

- movement tracking

- slot validation

- automated yard surveillance

RTLS ensures the YMS always knows:

- what vehicle is where,

- whether it is in the correct slot,

- and when a mis-stow needs correction.

Step 5: Integrate Everything Into a YMS, Location, Status, and Movement Logic

A structured yard layout becomes most powerful when paired with an intelligent Yard Management System.

5.1 Link VIN → Location → Status

The YMS should combine:

- booking data,

- vehicle dimensions,

- zoning rules,

- time windows,

- and the Z-B-R-S slot model.

5.2 Automate Status Based on Location

Avoid manual updates.

Let the system apply statuses such as:

- RTL (Ready to Load)

- PHD (Pending Hold for Customs)

- UNS (Unserviceable)

- PDI/Maintenance

5.3 Optimize Parking Assignments

A modern YMS should assign the best future-retrieval slot, not just the nearest empty one.

It must consider:

- ETD (estimated departure time)

- vehicle category

- required aisle width

- staging proximity

- expected retrieval path

This minimizes shunting and reduces vessel cycle time.

Step 6: Measure Results and Continuously Improve

Core KPIs of a well-designed yard include:

- >99.9% inventory accuracy

- reduction in internal shunting moves

- improved vessel turnaround

- faster staging operations

- fewer handling damage incidents

A yard designed using this structured framework becomes predictable, safe, and scalable, ready for digital transformation and automation.

Need Expert Support Designing or Digitizing Your RoRo Yard?

If you're planning a yard redesign, implementing a new zoning model, or integrating RTLS, Logisoft specializes in TMS, TOS, and YMS solutions specifically built for RoRo and Finished Vehicle Logistics.

We can help you:

- evaluate your current layout,

- design an optimized Zone–Block–Row–Slot model,

- build zoning logic for customs, staging, and compliance,

- integrate RTLS and digital mapping,

- and deploy a modern YMS that automates your location and status workflows.

👉 Contact us to begin your terminal’s yard optimization project.

Our experts are ready to help you transform your yard into a high-performance logistics operation.